A first silvering attempt yielding a result

After some unsuccessful tests caused by the lack of purity of the various products involved in the silvering process, and confusion between the different types of sugars (dextrose, glucose, sucrose…), a new attempt yielded a reflective and homogeneous deposit.

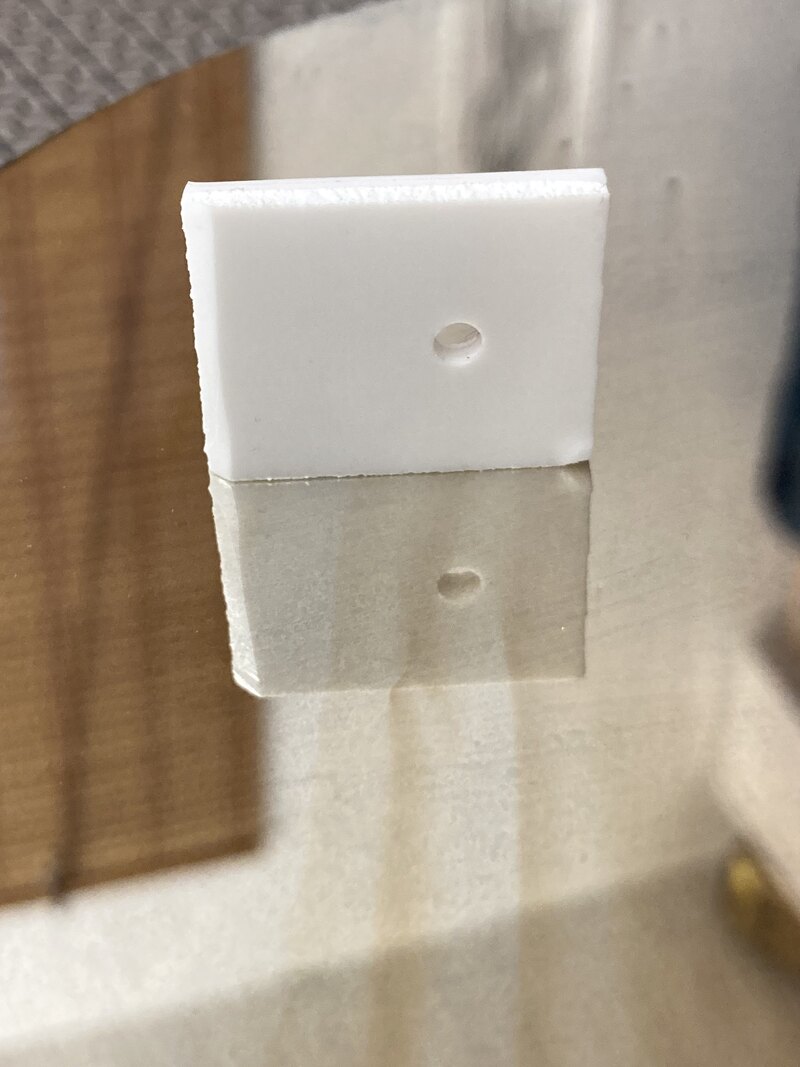

The coating is slightly translucent:

One can estimate its reflectivity with a block of teflon, photographed at 45°, placed on the mirror:

The Teflon block has its average RGB components at (194, 191, 186). Its reflection on the mirror is at (165, 158, 143). The reflectivity can therefore be calculated to be 0.82, or 82%. For a first coating, it is not too unsatisfactory, although it should be possible to reach more than 96%.

The process could be improved in many ways:

- Cleaning of the mirror left something to be desired, giving rise to brown streaks

- the purity of the various products could still be improved

- the amount of solution prepared was too small and this caused me difficulties

That said, this trial lays the foundation for autonomy in optical manufacturing and coating for my personal use.

The process followed is described in my previous post. Be careful to ensure that the brown precipitate dissolves properly when preparing the solution, which requires a little time.