Open XYZ platform for interferometry

I’m happy to release this printable XYZ platform for interferometry. It has been printed 3 times and improved at each print with ease-of-life features.

Find it on Printables : https://www.printables.com/fr/model/860316-xyz-platform-for-bath-interferometers or on Github : https://github.com/lucassifoni/xyz-table

It features :

- 40mm+ travel

- Coarse / Fine motions via big handles

- M4 commodity hardware only

Please know your printer and use the TOLERANCE TEST

You have to print everything flawlessly for smooth motion. To determine what STLs to use, please print the TOLERANCE TEST. It should slide freely, with a bit of sanding if you mis-placed the seam while slicing. Pay attention to the seam position ! Seam traps are on the roadmap but not implemented yet.

Why is the tolerance test so big ?

Good question : I found that my smaller tolerance tests (one rail only) did not give correct information as whether a whole stage would be smooth.

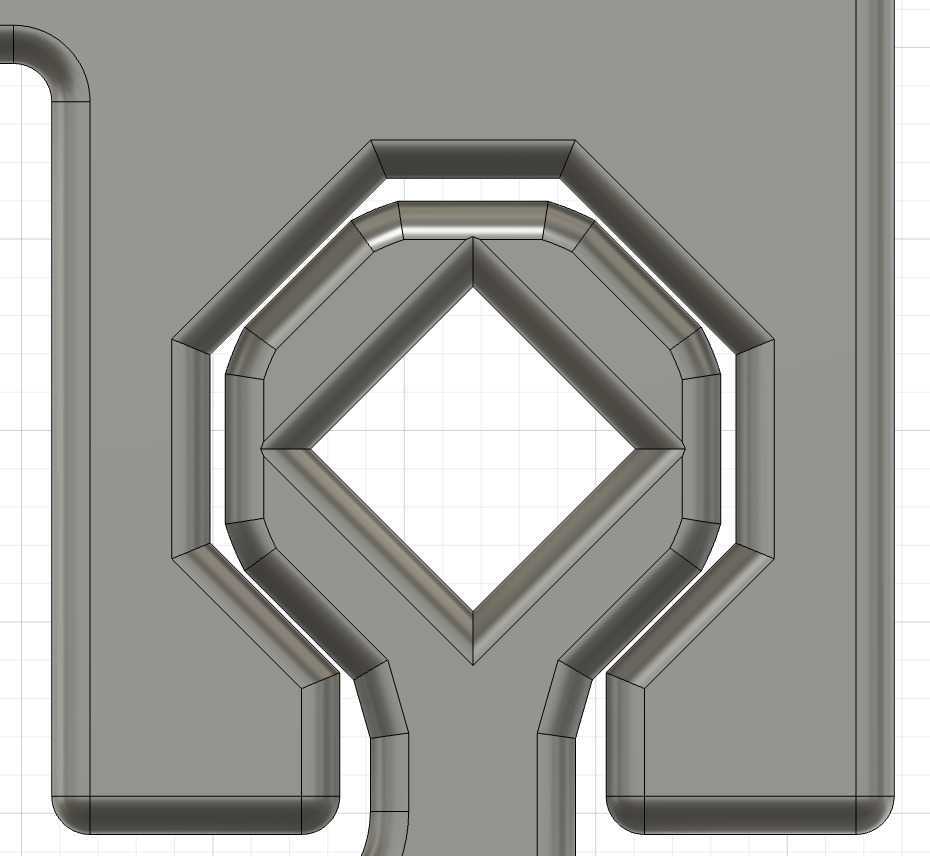

The tolerance is the fine space in this screenshot. The smallest you can print, the best :

| Name | Value | Printed and tested |

|---|---|---|

| Tightest | 0.07mm | ✅ (Bambu P1S) |

| Tight | 0.1mm | |

| Easy | 0.125mm |

Prints BOM

- Print the TOLERANCE TEST and choose accordingly

- Print everything in the

Commonfolder in the quantities listed in file names - Print everything in the folder corresponding to your chosen tolerance

Vitamins BOM

| Design. | Quantity |

|---|---|

| M4 rod | 3 |

| M4 nut | 12 |

| M4 screw x 14mm | 16 |

| Superglue | Some |

Only uses M4 rods and M4 screws as vitamins. Superglue is used to lock the nuts and suppress Z axis wobble at the joint with the Y axis.

A few tips :

- Dry your filament.

- Do not print too fast.

- Use PETG

- Re-tap the screw holes before assembly

- Tap the carrier blocks with oil before assembly